Auto Bill of Materials

The Auto Bill of Materials (Auto BoM) feature is intended for simple manufacturing processes that don't require the added functionality and overhead associated with the full manufacturing features provide by the

Users must create a material list suitable for one-step processing, similar to manufacturing, which is converted into an item, and can then be added to a sales transaction as a single item.

The following restrictions apply to the Auto BoM feature:

•When an Auto BoM item is returned, components will not be returned if the item is returned to stock. The on-hand quantity will increase for the Auto BoM parent SKU, crediting the sale and cost of sale for the Auto BoM item only. The same applies to Vendor returns.

•Auto BoM items cannot be used in Direct Ship.

•Transfers are not permitted at this time.

•On-hand quantities of 0 are permitted. Material quantities are manually adjusted if the on-hand quantity is greater than 0. If the on-hand quantity falls below 0, a work order will be created for the item.

Setting up Auto Bill of Material (Auto BoM)

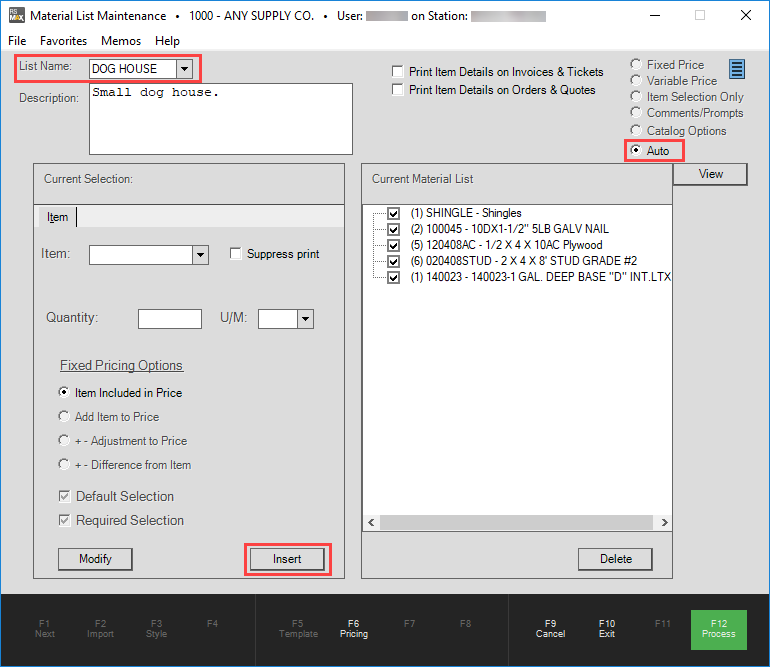

1.You must first create a new Material List. Navigate to

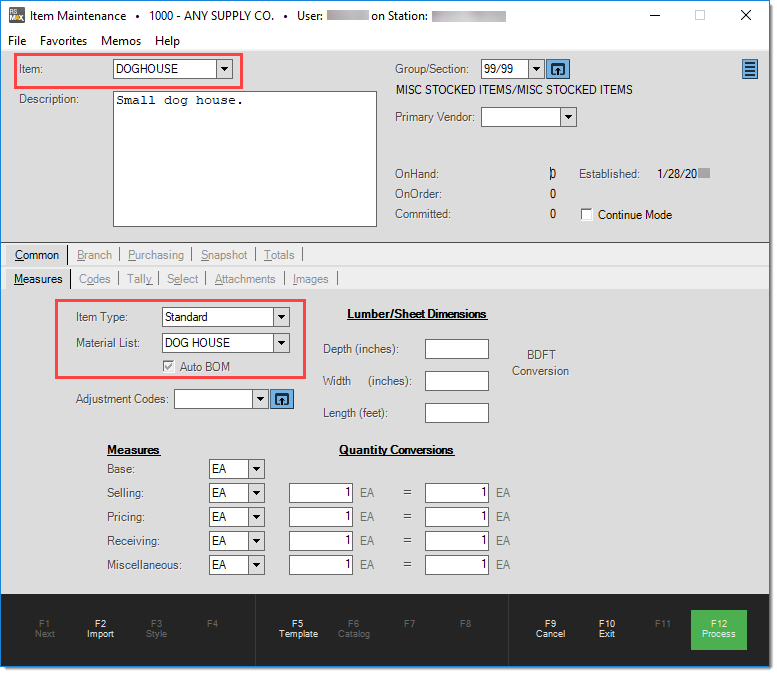

2.Open the Item Maintenance dialog window by going to POS > Database > Item, and create a new item. The Item name cannot be the same as the Material List name. On the Common / Measures tab, select "Manufactured" from the "Item Type" field, and the desired material list from the "Material List" drop-down list. You must select a list that used the "Auto" option in Material List Maintenance. Enter the desired Measures and Quantity Conversions.

3.On the Common / Codes tab, the option "Track Qty" must be set to Y.

4.On the Branch / Codes tab, the "Stocked" field must be set to Y.

5.On the Branch / Pricing tab, pricing must be entered.

6.Press F12 to process the new Auto BoM item. Note that if the mandatory fields are not set, a task list will appear.

Using Auto BoM at Point of Sale

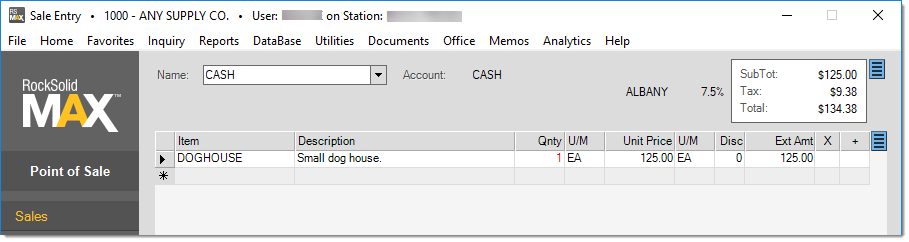

1.From POS, enter the item created in Item Maintenance. If all items listed in the Materials List are on-hand, no work order will be created. If some or all items are not available, a work order will be created when the sale is processed (F12).

Quick Links